Milling Solutions with iMachining® Technology

PRODUCT OVERVIEW

SolidCAM Milling

SolidCAM’s Milling modules provide a streamlined, intuitive interface for defining CNC machining operations directly from parts, assemblies, and sketch geometry.

Whether you are programming 2.5D prismatic parts, standard 3-axis jobs, indexial 4/5-axis, or full simultaneous 5-axis machining, SolidCAM Milling offers unmatched flexibility to scale and grow with your business.

iMachining® – Faster, Smarter, Stronger

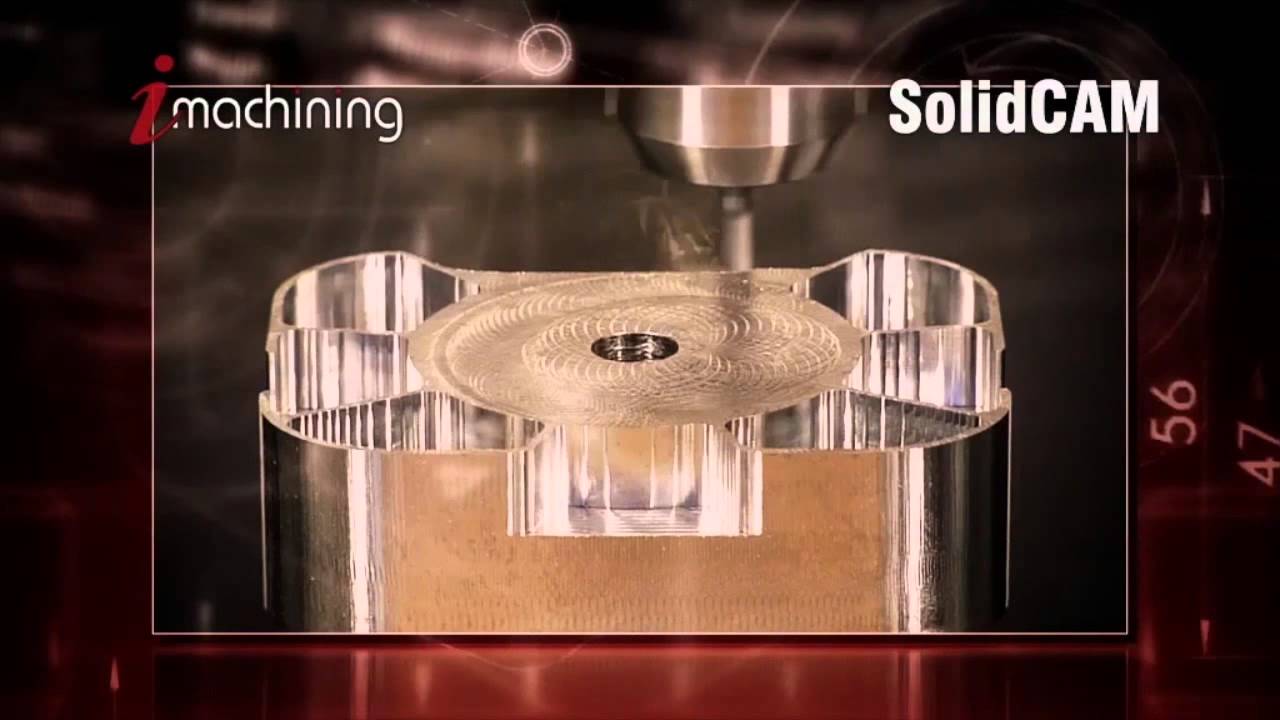

Available in all milling packages, iMachining technology leverages patented algorithms and intelligent toolpath strategies to dramatically reduce cycle times while extending tool life.

Why Choose SolidCAM Milling with iMachining

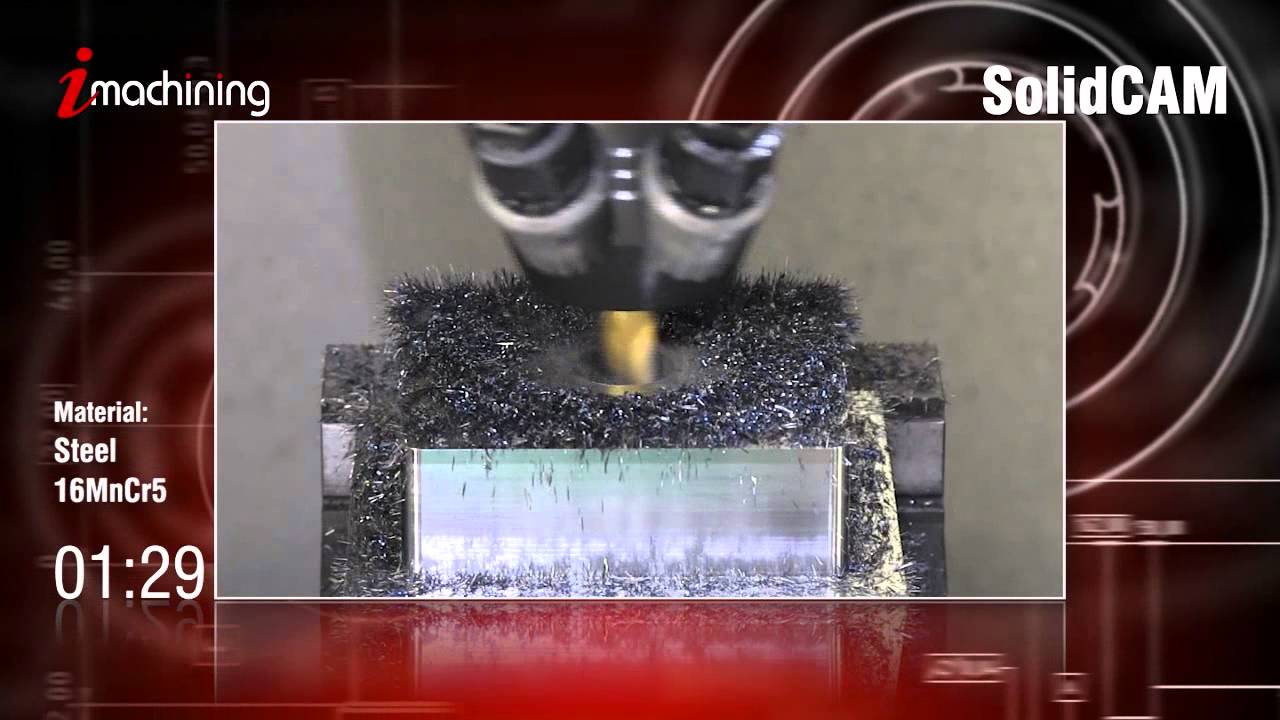

Cut Cycle Times by up to 70%

Machine parts faster thanks to optimized tool engagement, constant chip load, and high-speed strategies that minimize wasted motion.

Lower Costs Through Longer Tool Life

Adaptive feeds and speeds, constant load machining, and optimized cutting angles protect tools from premature wear and reduce replacement costs.

Reduce Programming Effort and Errors

Automation tools like feature recognition and intelligent wizards minimize manual setup, saving time and reducing the chance of mistakes.

Milling + iMachining Videos

Milling + iMachining Videos

3:46

5:56

5:15

0:06

0:08

0:07

0:07

0:13

Key Features

Check out the standout features you get with Milling + iMachining, including support for 2.5D, 3-axis, and advanced axis work in SolidCAM:

iMachining Technology Wizard

Calculates optimized feeds, speeds, and stepovers automatically for your specific machine, material, and tooling.

SolidCAM Toolkit

Advanced tool management with 3D imports, shaped tools, assemblies, smart cutting conditions, and fully linked components.

Process Templates

Save and reuse complete operation sets to program new parts faster, with consistent results every time.

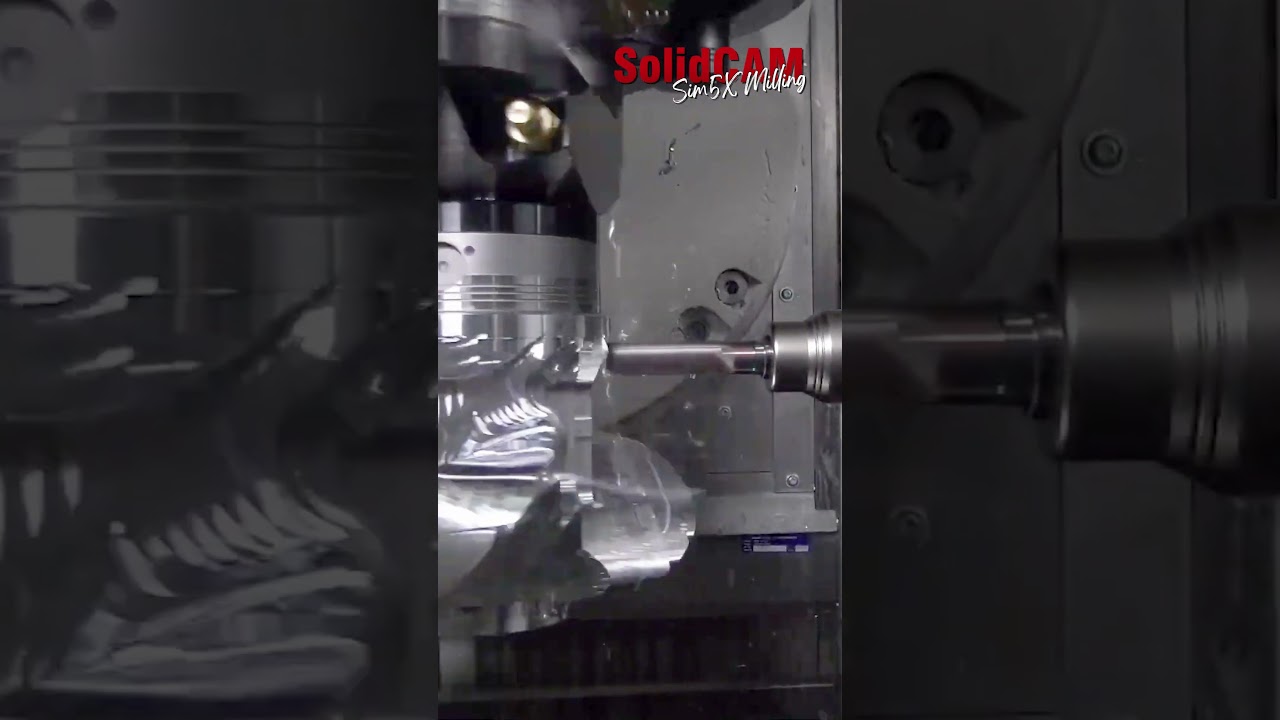

Full Machine Simulation

Provides accurate, collision-checked simulations of machines, fixtures, and toolpaths before actual machining.

High Speed Machining

Provides powerful roughing strategies (contour, hatch, hybrid rib-roughing, rest-roughing) plus finishing paths with minimized retractions and smooth lead-ins and outs.

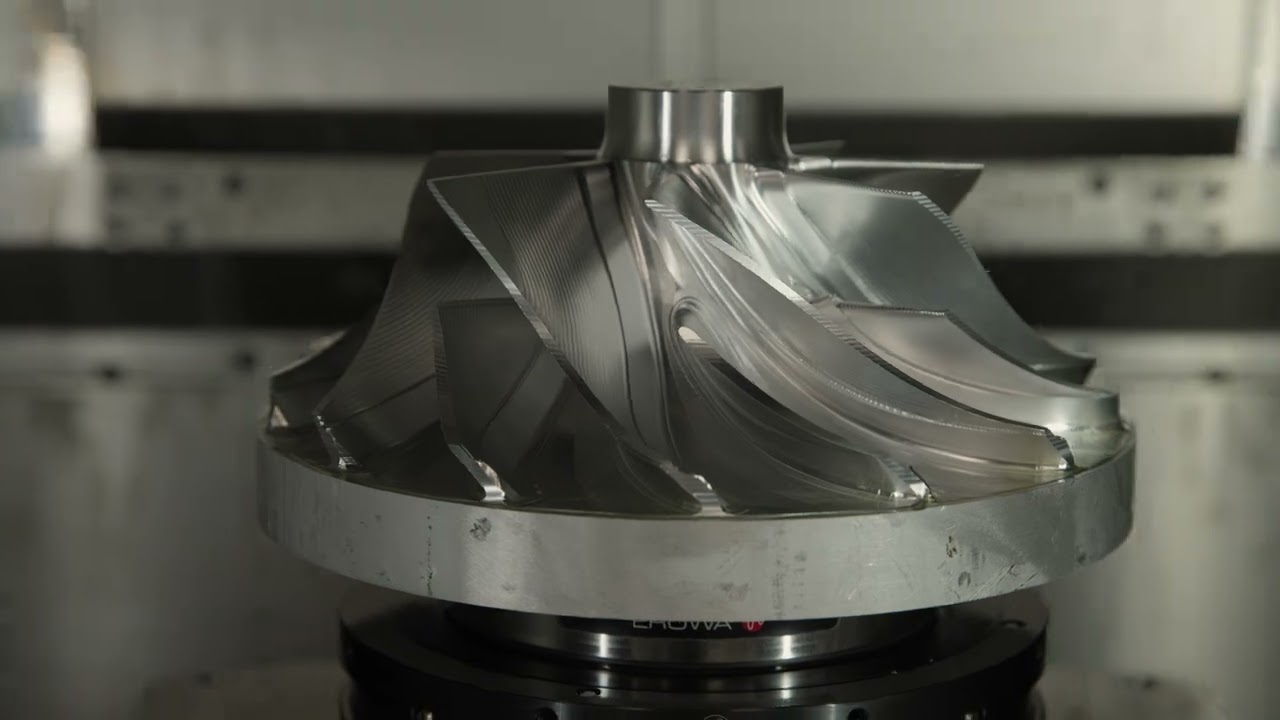

Simultaneous 5-Axis Strategies

Includes swarf cutting, blade and port machining, contour 5-axis, and advanced collision avoidance for complex shapes.